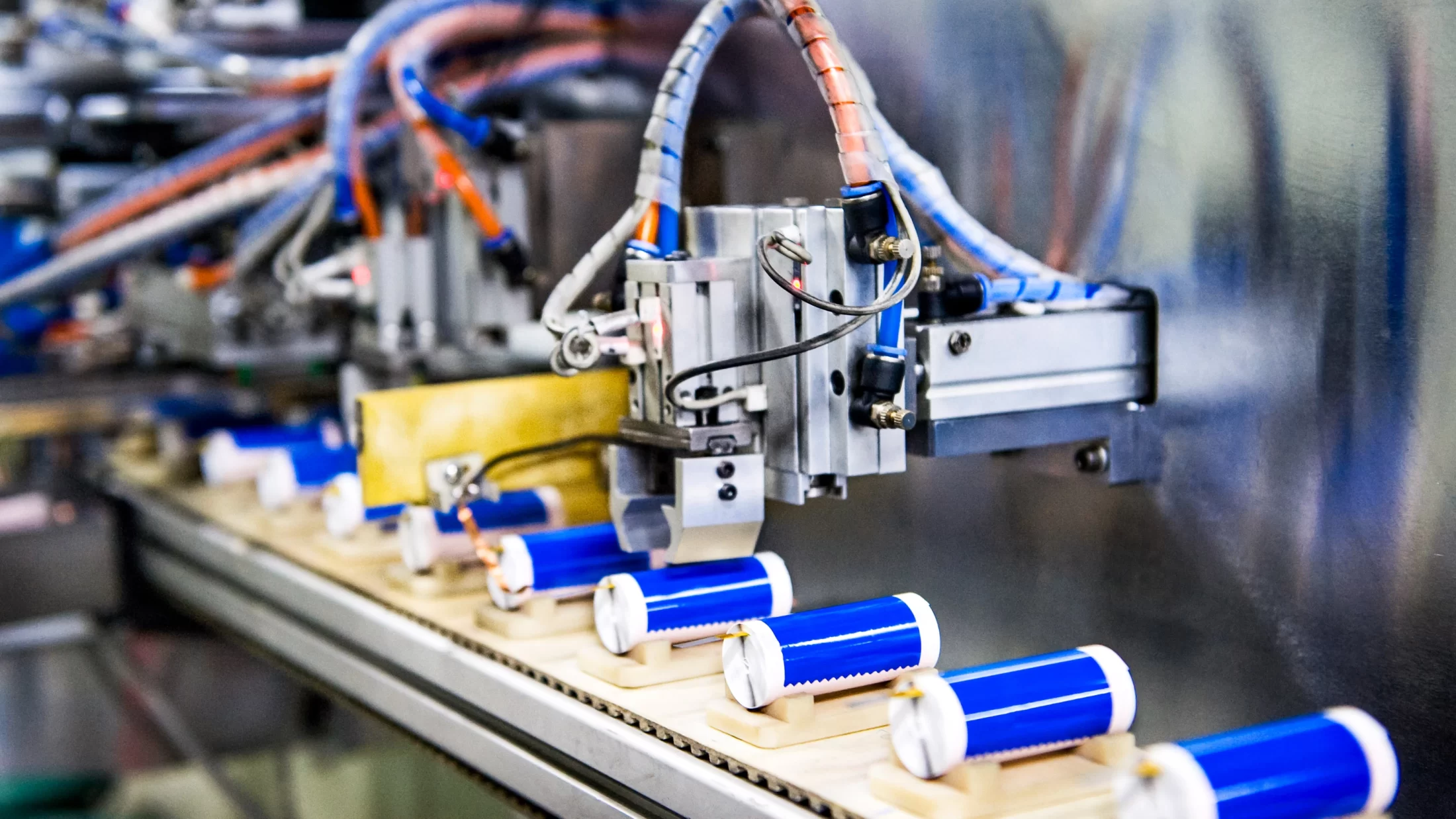

Sodium-ion Batteries

Batteries have become an integral part of our daily lives, powering everything from our smartphones to electric vehicles. Lithium-ion batteries have long dominated the market due to their high energy density and long cycle life. However, the demand for energy storage solutions that are more sustainable, affordable, and abundant has led to the exploration of alternative battery technologies. Sodium-ion batteries have emerged as a promising candidate to address these challenges.

As the demand for cleaner and more sustainable energy solutions continues to rise, researchers and engineers are constantly seeking innovations in battery technology. One such innovation that has gained significant attention in recent years is sodium-ion battery technology.

Sodium-ion batteries (SIBs) represent a compelling alternative to the well-established lithium-ion batteries (LIBs). They are part of a broader effort to diversify the battery landscape, offering unique advantages and addressing some of the limitations associated with traditional lithium-ion technology.

Chemistry of Sodium-Ion Battery

Sodium-ion batteries use sodium ions (Na+) as the charge carriers instead of lithium ions (Li+), which are used in lithium-ion batteries. The basic principle of operation is similar, involving the movement of ions between a positive cathode and a negative anode.

A “sodium-ion battery” is not a specific chemical compound or formula like a traditional chemical substance. Instead, it refers to a type of battery technology that uses sodium ions (Na+) as charge carriers. These sodium ions move between the positive and negative

Electrodes within the battery during charging and discharging cycles.

Chemical Components

Cathode: The cathode is the positive electrode, and it typically contains a compound that can accept sodium ions during charging and release them during discharging. Common cathode materials in sodium-ion batteries include sodium cobalt oxide (NaCoO2), sodium iron phosphate (NaFePO4), and other sodium-based compounds.

Anode: The anode is the negative electrode, and it typically contains a material capable of storing or intercalating sodium ions during charging and releasing them during discharging. Common anode materials in sodium-ion batteries include hard carbon (graphite-like materials) and other sodium-intercalation compounds.

Electrolyte: The electrolyte is the conductive medium that allows the movement of sodium ions between the cathode and anode. It’s typically a sodium salt dissolved in a solvent.

Separator: A separator is a porous membrane that physically separates the cathode and anode to prevent short circuits while allowing the flow of sodium ions.

The chemical reactions involved in a sodium-ion battery are complex and involve the movement of sodium ions between the cathode and anode, as well as redox reactions within the electrode materials.

Anode Materials

- Hard Carbon: Hard carbon materials, often derived from petroleum coke or other carbonaceous sources, are commonly used as anodes in sodium-ion batteries. These materials have a high capacity for sodium ion storage and can accommodate the intercalation of sodium ions during charging.

- Sodium Titanates: Materials like sodium titanate (Na2Ti3O7) and sodium titanate nanotubes are also used as anode materials in some sodium-ion battery designs. They offer good cycling stability and sodium ion storage capacity.

- Phosphorus-Based Compounds: Phosphorus-based compounds, such as sodium iron phosphate (NaFePO4), have been explored as anode materials due to their high theoretical capacity and stability.

Cathode Materials

- Sodium Cobalt Oxide (NCO): Sodium cobalt oxide (NaCoO2) is a common cathode material in sodium-ion batteries. It can reversibly store and release sodium ions during charging and discharging cycles. However, it may contain cobalt, which is a relatively expensive and less abundant element.

- Sodium Iron Phosphate (NFP): Similar to its use as an anode material, sodium iron phosphate (NaFePO4) is also employed as a cathode material in sodium-ion batteries. It offers good stability and safety characteristics.

- Prussian Blue and Its Derivatives: Prussian blue (sodium iron hexacyanoferrate) and its derivatives are another class of cathode materials used in sodium-ion batteries. They are known for their high cycling stability and safety.

- Sodium Vanadium Phosphate: Some sodium-ion batteries use cathodes based on sodium vanadium phosphate compounds (e.g., Na3V2(PO4)3) due to their good electrochemical performance.

Why Sodium-Ion Batteries over lithium-ion batteries?

Some of the potential advantages of sodium-ion batteries over lithium-ion batteries:

- Abundance of Sodium: Sodium is one of the most abundant elements on Earth, and its availability is not as limited as lithium. This can make sodium-ion batteries more cost-effective in terms of raw materials, potentially reducing the overall cost of the batteries.

- Lower Cost: As mentioned, the abundance of sodium can contribute to lower material costs. Additionally, sodium-ion batteries may benefit from simplified manufacturing processes, such as the use of less expensive electrolytes or the ability to use less expensive cathode materials, which can further reduce costs.

- Reduced Environmental Impact: Sodium-ion batteries may have a lower environmental impact due to the greater abundance of sodium and fewer supply chain concerns compared to lithium-ion batteries. However, the overall environmental impact also depends on factors such as the mining and extraction of raw materials.

- Safety: Sodium-ion batteries are generally considered safer than lithium-ion batteries, primarily because sodium is less reactive and has a lower risk of thermal runaway or fire. This improved safety profile is advantageous for applications where safety is a top priority.

- Large-Scale Energy Storage: Sodium-ion batteries may find applications in large-scale energy storage due to their cost-effectiveness and safety. They can be used for grid energy storage, renewable energy integration, and stabilizing power distribution networks.

- Compatibility with Existing Infrastructure: Sodium-ion batteries may be designed to be compatible with existing manufacturing and infrastructure used for lithium-ion batteries. This can facilitate a smoother transition to new battery technologies.

Companies working on sodium-ion battery technology

CATL (Contemporary Amperex Technology Co. Ltd.)

CATL is a prominent Chinese battery manufacturer known for its lithium-ion batteries. They have been investing in research and development of sodium-ion batteries as an alternative to lithium-ion technology.

Toshiba

Toshiba has been a pioneer in the development of sodium-ion batteries. They have announced research efforts to advance sodium-ion battery technology.

Faradion

Faradion, a UK-based company, has been working on sodium-ion batteries and has received funding for research and development projects. As per some reports well known Indian Group Reliance Industries has paid 135 Million dollars to purchase Faradion.

Sakura Battery

Sakura Battery, a Japanese company, has also been involved in sodium-ion battery research and development.

Ionic Materials

Ionic Materials, a U.S.-based company, has been researching and developing solid-state electrolyte materials for various types of batteries, including sodium-ion batteries.

Ilika

Ilika, a UK-based materials company, has been working on advanced materials for energy storage applications, including sodium-ion batteries.

Comparison of Sodium Ion Battery and Lithium Ion Battery

| Aspect | Sodium-Ion Batteries | Lithium-Ion Batteries |

| Abundance of Raw Materials | Sodium is more abundant. | Lithium is less abundant. |

| Cost | Generally expected to be cheaper due to abundant sodium. | Materials like cobalt can make lithium-ion batteries more expensive. |

| Energy Density | Typically lower energy density, which can affect driving range in electric vehicles. | Higher energy density, allowing for longer driving ranges in EVs. |

| Cycle Life | Historically, sodium-ion batteries had lower cycle life, but improvements are being made. | Lithium-ion batteries typically have good cycle life. |

| Safety | Considered safer due to lower reactivity of sodium compared to lithium. Reduced risk of thermal runaway. | Generally safe but can be prone to thermal runaway if damaged or abused. |

| Environmental Impact | Potentially lower environmental impact due to sodium’s abundance and fewer supply chain concerns. | Concerns about the environmental impact of lithium mining and extraction. |

| Charging Speed | Charging and discharging rates can vary depending on materials but may be slower than lithium-ion batteries. | Lithium-ion batteries often have faster charging capabilities. |

| Applications | Potential for large-scale energy storage, grid applications, and electric vehicles. | Widely used in electric vehicles, portable electronics, and energy storage systems. |

| Research and Development | Active research to improve performance, energy density, and cycle life. | Ongoing research to enhance performance and safety. |

Read More:- Types of Battery Chemistries: From Li-ion to Lead-Acid