New Delhi: The dearth of lithium-ion batteries can create doubt for buyers of electric vehicles (EV). This problem can be resolved through alternative battery technologies or energy storage systems. Lithium is the biggest energy provider and an expensive unit in an EV. India imports a large amount of lithium. Though in recent months lithium mines have been found in Jharkhand and Gujarat, the lack of appropriate technology to convert it into batteries acts as an obstacle. Metal-air battery (technology) is an emerging technology for EVs which is all set to be commercialized this year. However, the question arises, is it really an alternative to lithium batteries? Why is it not adopted yet? The following FAQs answer such questions.

Q: What is Metal-Air technology for EVs and how does it work?

Metal-air batteries can be a practical breakthrough with substitute energy storage technology. It is a long-range, budget-friendly, lightweight, and recyclable source of energy that can arguably be a saviour in the EV market.

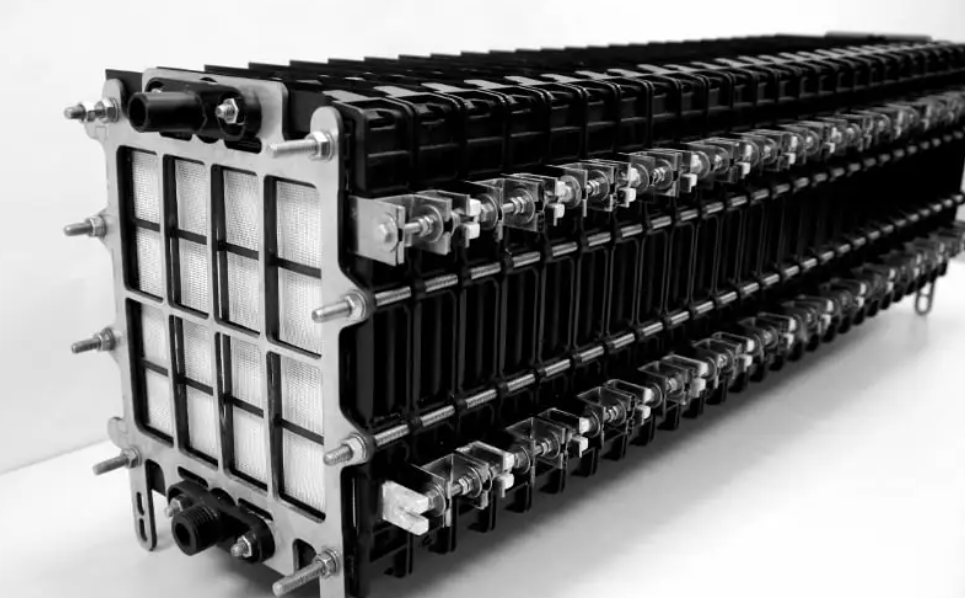

Metal-air batteries were invented in 1978, taking the oxygen (atmosphere) as the cathode, the electron receiver, and metal as anode, the electron distributor paired up with water-electrolyte. The anode is designed for cheap metals like zinc, aluminum, and iron.

The aluminum (metal used) in vehicles’ batteries produce electricity when exposed to atmospheric oxygen. If the batteries are effective then they could have a higher range than the lithium batteries. The technology behind these aluminum-air batteries could be a revolutionary step in the auto industry if it is practically effective.

Q: What are the hurdles for lithium batteries?

For the large-scale adoption of EVs, India needs to make it budget-friendly for people. Cost can be said to be one of the biggest barriers to the growth and adoption of EVs. Battery expense is one of the major expenditures in manufacturing an EV. To curb this issue newer technologies have to be adopted with a shift to metal-air batteries and locally available minerals should be there.

The second hurdle is the range issue of lithium-ion batteries. As of October 2021, there were 427 installed EV charging stations in India. The growing EV demand will not be fulfilled with the present number of EV charging stations across the country. Lithium-ion batteries need to be charged every 200-odd-km, implying it requires more charging stations and has a lower range. However, metal-air technologies can lead to development as they provide a longer range than the lithium-ion one.

An appropriate R&D for modern lightweight elements in EVs, can curb the costs and reduce the cost of commercialization of the elements.

Q: Which companies have planned to use metal-air technologies for EVs?

Phinergy: Phinergy is Israel’s clean energy company, whose key role is focused on AI-Air business. has signed its joint venture with Indian Oil Corporation to develop aluminum-air.

Tata Motors and Mahindra both the leading Indian OEMs, have collaborated with Phinergy for the development of AI-Air technology. During the Auto Expo 2023 at Phinergy’s booth, a Tigor EV equipped with Phinergy’s battery pack was demonstrated.

Anand Kulkarni, VP, of Tata Passenger Electric Mobility, had told ETAuto earlier that AI-Air technology has a promising future, when we talk about alternative battery chemistries even though no production of cars is there. Adding to that he said aluminum air batteries should come as a booster for people who want to travel longer distances.

Maruti Suzuki and Ashok Leyland have also signed a Letter of Intent (LoI) with the IOC Phinergy JV that occurred earlier.

Log9: Log9 Materials is also planning to start its project on aluminum-air in this calendar year. Log9 is a Bengaluru-based start-up that also recycles lithium-ion batteries along with AI-Air solutions.

Q: What are the pros and cons of metal-air batteries?

Pros

1) Making it more accessible: Due to the limited availability of lithium in the current scenario. These batteries would help in making EV batteries commonly available as the metal required is available in India.

2) EV batteries are cost-effective: Owing the production of batteries in India, it would reduce imports leading to a cut in the cost of batteries and EVs affordable and budget-friendly for everyone. Due to the reduced cost of EVs, it opens an opportunity to potential buyers.

3) Environment-friendly: India being the 3rd highest producer of carbon emissions in the world, Indian govt. Aims to shift away from ICE in the future. Lithium-ion batteries are also hazardous for the environment if not decomposed properly. Thus, metal-air technology batteries are recyclable in nature thus making it a good and safer option for the environment.

4) Lighter in weight: Metals like aluminium are lightweight materials that produce energy equivalent or more than lithium-ion batteries. The energy density can be approximately 8.1 kWh/kg, while the average density of lithium-ion cells is approximately 200 kWh/kg. Thus it makes a huge difference, and as per experts, the final energy density difference could be around 8X and 15X.

Cons

1) Not rechargeable: Metal-air batteries unlike lithium-ion batteries can not be recharged. Once a metal-air battery is depleted of its energy (power), the battery has to be replaced instead of being recharged.

Indian Oil is working to solve this issue, they are planning to set up battery-swapping facilities in thousands of gas stations across India. These stations will be altered as the battery replacement station for metal-air batteries. The goal is to make the swapping easy and as quick as it takes to fill a gas tank.

2) High power storage: Metal-air batteries can work out only in high-power storage that requires more than 2000 Wh/kgs or where grid-level electrical storage is used. It can also be used for heavy vehicles like trucks that are running 1000 km or 2000 km, where it acts as an energy booster, where continuous energy is necessary.

Q: Why metal-air technology cannot be a substitute?

Several companies have tried using metal-air technology for EVs but left it midway as it cannot be recharged. There are metal-air batteries available(in zinc, aluminum, and iron) with different densities however, aluminum is widely used as it is easier to replace than others and then recycling of batteries is done.

The Mobility sector cannot see metal-air technology as a substitute for lithium batteries as it is not rechargeable and thus its complexities increase. It is expensive to replace batteries every time after its usage though it provides high energy storage capacity. However, it can work in grid electricity storage scenarios or heavy truck scenarios as mentioned above where continuous or high energy is required. However in the future with adequate R&D on metal-air technology, it may be made more applicable in the mobility sector.