Lithium Nickel Cobalt Aluminum Battery

Introduction

In our quest for cleaner and more efficient energy sources, lithium-ion batteries have emerged as a frontrunner in powering the devices we use daily. As the demand for electric vehicles (EVs) and renewable energy storage solutions continues to rise, the need for advanced battery technologies becomes more pressing. Enter the Lithium Nickel Cobalt Aluminum Battery, often abbreviated as NCA. This remarkable battery chemistry is making waves in the world of energy storage due to its impressive energy density, reliability, and performance.

Chemical Formula:

The Lithium Nickel Cobalt Aluminum Battery derives its name from its key chemical components: lithium, nickel, cobalt, and aluminum. Its chemical formula is typically represented as

LiNiCoAlO2

This unique combination of elements plays a crucial role in the battery’s performance and overall efficiency.

Working of Lithium Nickel Cobalt Aluminum Battery

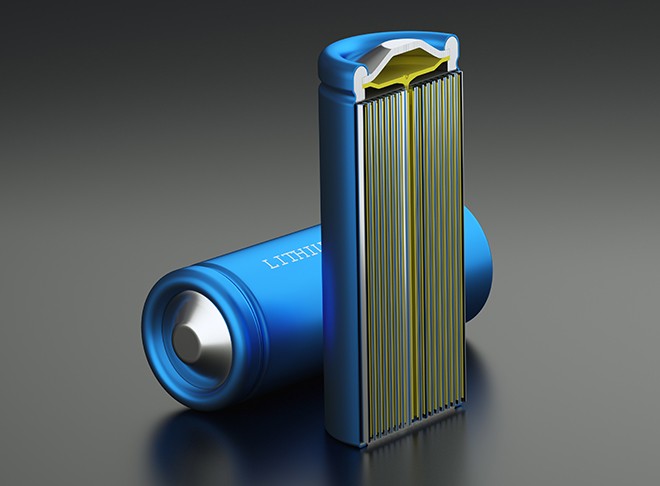

The working of a Lithium Nickel Cobalt Aluminum (NCA) battery is based on the principles of electrochemical reactions during both charging and discharging cycles. These reactions involve the movement of lithium ions between the battery’s anode and cathode, accompanied by electron flow through an external circuit.

-

Charging Process:

During the charging process of an NCA battery, electrical energy from an external source is supplied to the battery, causing lithium ions to move from the cathode to the anode. Here’s a step-by-step breakdown of the electrochemical reactions that occur:

- Anode (Negative Electrode): The anode in an NCA battery is typically made of graphite, a material that can intercalate (absorb) lithium ions. During charging, lithium ions from the cathode are extracted and move through the electrolyte to the anode.

- Cathode (Positive Electrode): The cathode is composed of the LiNiCoAlO2 compound. As lithium ions are removed from the cathode, nickel, cobalt, and aluminum ions are left behind, creating vacancies in the crystal structure. These vacancies are filled with electrons from the external circuit.

- Electrolyte: The electrolyte, which is typically a lithium salt dissolved in a solvent, facilitates the flow of lithium ions between the anode and cathode while preventing the direct flow of electrons. It ensures that the charge and discharge reactions remain separate.

-

Discharging Process:

During the discharging process, the battery supplies electrical energy to an external device or system. Lithium ions now move from the anode to the cathode, and the stored energy is released. Here’s how the electrochemical reactions unfold:

- Anode (Negative Electrode): As the battery discharges, lithium ions are released from the anode and travel through the electrolyte to the cathode.

- Cathode (Positive Electrode): The lithium ions arriving at the cathode are inserted into the crystal structure of the LiNiCoAlO2 compound. This results in the reduction of nickel, cobalt, and aluminum ions and the release of stored energy, which is harnessed to power external devices.

- Electrolyte: The electrolyte allows the flow of lithium ions between the anode and cathode, facilitating the discharge process while preventing the direct flow of electrons.

Selection of Cathode and Anode for Lithium Nickel Cobalt Aluminum Battery:

-

Anode (Negative Electrode)

- Material: The anode material in an NCA battery is typically made of graphite, a form of carbon. Graphite is a popular choice due to its ability to efficiently intercalate (absorb and release) lithium ions during charge and discharge cycles. Graphite anodes are known for their stability and low irreversible capacity loss, contributing to a long cycle life.

Advantages: Graphite anodes offer excellent reversibility, which means they can efficiently store and release lithium ions without significant degradation over time. They have a high coulombic efficiency, which is essential for maintaining battery capacity.

-

Cathode (Positive Electrode):

- Material: The cathode material in an NCA battery is composed of the LiNiCoAlO2 compound. This compound contains lithium, nickel, cobalt, and aluminum. The specific ratio of these elements can vary, but the most common composition is LiNiCoAlO2.

Advantages: The use of LiNiCoAlO2 as the cathode material in NCA batteries offers several advantages:

- High Energy Density: NCA cathodes provide a high energy density, allowing the battery to store a significant amount of energy in a compact space. This high energy density makes NCA batteries suitable for applications where size and weight constraints are critical, such as electric vehicles (EVs).

- Good Conductivity: NCA materials exhibit excellent electrical conductivity, which aids in the rapid charge and discharge of the battery. This is particularly important in EVs, where fast charging is essential to enhance convenience and driving range.

- Thermal Stability: NCA cathodes are known for their thermal stability, which reduces the risk of thermal runaway and enhances the safety of the battery.

- Long Cycle Life: NCA cathodes can endure a large number of charge and discharge cycles, contributing to the overall lifespan of the battery.

Advantages of Lithium Nickel Cobalt Aluminum Battery:

- High Energy Density: One of the most significant advantages of NCA batteries is their high energy density. This means they can store a large amount of energy in a relatively compact package, making them ideal for applications where space is limited, such as electric vehicles.

- Long Cycle Life: Lithium Nickel Cobalt Aluminum Batteries are known for their long cycle life, which means they can endure a substantial number of charge and discharge cycles before their capacity significantly degrades. This characteristic increases the lifespan of the battery and reduces the need for frequent replacements.

- Fast Charging: NCA batteries can be charged rapidly due to their excellent conductivity. This feature is especially valuable for electric vehicles, where quick charging is essential to improve convenience and range.

- High Voltage Output: These batteries provide a higher voltage output compared to some other lithium-ion chemistries, which can be advantageous in certain applications.

- Wide Temperature Range: NCA batteries are known for their ability to operate effectively over a wide temperature range, making them suitable for use in diverse climates.

Top 10 manufacturers of Lithium Nickel Cobalt Aluminum Battery:

1. Panasonic Corporation

Panasonic is a well-known manufacturer of lithium-ion batteries, including NCA batteries, for various applications, including electric vehicles.

2. G Chem

LG Chem is a leading South Korean battery manufacturer that produces NCA batteries for electric vehicles and energy storage systems.

3. Samsung SDI

Samsung SDI, another South Korean giant, is actively involved in the production of advanced lithium-ion batteries, including NCA-based batteries for various applications.

4. BYD Company

BYD, a Chinese multinational company, is a significant player in the electric vehicle industry and produces NCA batteries for its vehicles.

5. CATL (Contemporary Amperex Technology Co. Ltd.)

CATL is a major Chinese battery manufacturer known for producing various lithium-ion battery chemistries, including NCA batteries, for electric vehicles and energy storage.

6. Toshiba Corporation

Toshiba is a Japanese conglomerate that manufactures NCA batteries for a range of applications, including industrial and automotive use.

7. SK Innovation

SK Innovation, based in South Korea, is involved in the production of NCA batteries for electric vehicles and energy storage systems.

8. CALB (China Aviation Lithium Battery Co., Ltd.)

CALB is a Chinese company specializing in lithium-ion battery manufacturing, including NCA batteries for electric vehicles and renewable energy storage.

9. Amperex Technology Limited (ATL)

ATL, based in China, is a prominent lithium-ion battery manufacturer that produces NCA batteries used in various electronic devices and electric vehicles.

10. EVE Energy

EVE Energy, also based in China, is engaged in the production of lithium-ion batteries, including NCA batteries, for electric vehicles and other applications.

Read More:- Lithium Iron Phosphate Battery: Working Process and Advantages