It is not just AI, automakers are getting big on a number of technologies to make automobiles gadget-like, industry experts told ET.

“The mix of 5G, cloud, and edge computing offers a strong cocktail of digital technologies that can transform automobiles into extremely sophisticated and smart objects,” Vinod Gopinathan, Chief Information Officer, Ashok Leyland, told ET.

“AI tools like GPT can be leveraged for tasks ranging from customer assessment, recommendations, and negotiation, to vehicle purchase, maintenance, and disposal”, he said.

Generative Pre-trained Transformers (GPT) are a family of neural network models that use the transformer architecture and are used in generative AI applications such as ChatGPT.

“At Ashok Leyland, AI-powered Computer Vision-enabled equipment is extensively deployed in the manufacturing lines for manufacturing quality monitoring. On the ground, approximately 1,50,000 vehicles are integrated with iAlert, the company’s connected vehicle platform”, Gopinathan said.

Gopinathan also added that Hubble.ai, an advanced AI-powered Analytics platform transformed their transactional data into insights and foresight, empowering businesses with a wide array of functionalities to drive data-driven decision-making.

“The automobile industry is among the few sectors that have adopted AI and Metaverse to revolutionize sales and promotion. Bots will become more versatile and intelligent, handling structured and unstructured tasks. As a result, organizations will achieve greater productivity levels and uncover valuable business insights”, said Hasit Trivedi, Chief Technical Officer (CTO) of Digital Technologies and Global Head – AI, Tech Mahindra.

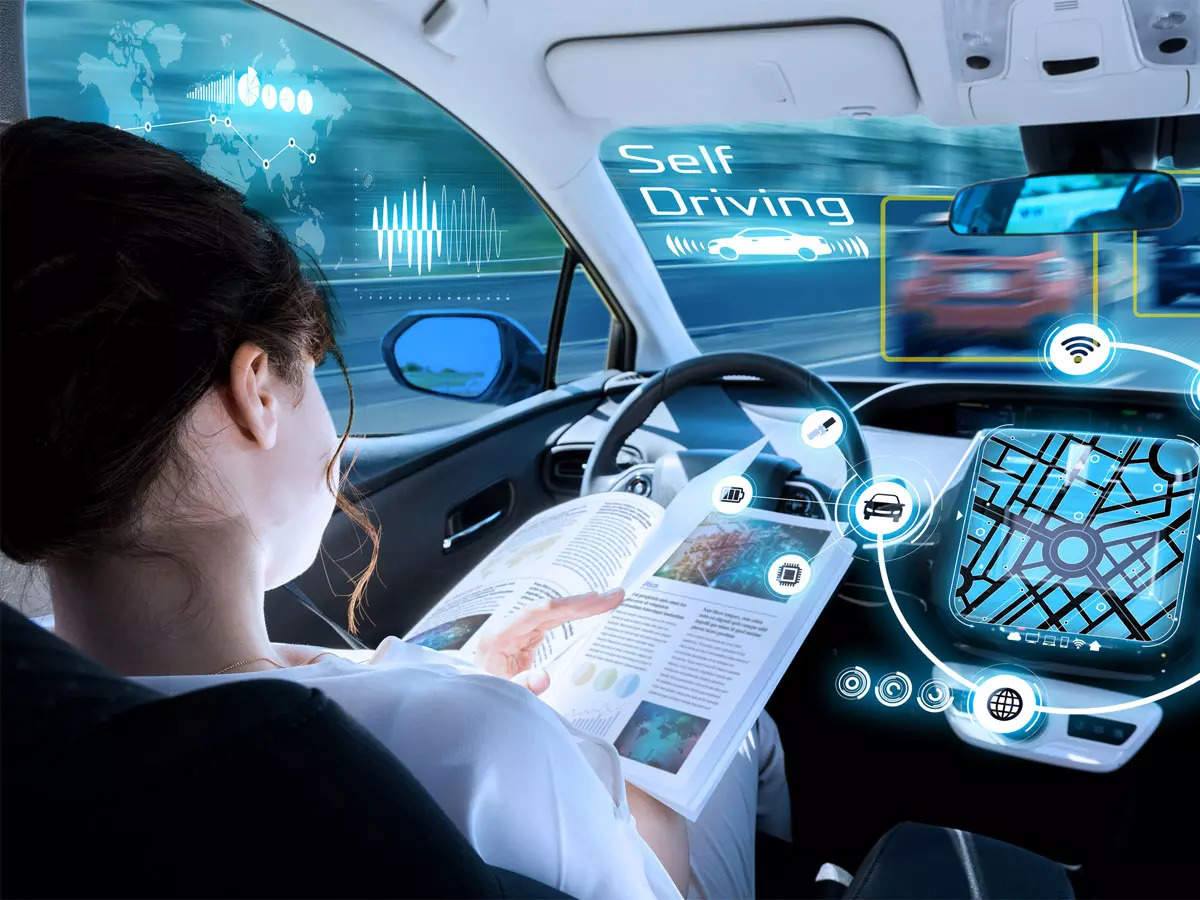

Metaverse combines social media, online gaming, augmented reality (AR), virtual reality (VR), and cryptocurrencies, allowing users to interact virtually. Trivedi said that the automotive industry was focusing on several trends, such as Autonomous vehicles, Advanced driver assistance systems (ADAS), Light Detection and Ranging (LiDAR), and RADAR technologies, which were being heavily researched and developed by automobile companies worldwide.

“In addition, the industry is investing in Connected Care and Car networking, which allows for real-time monitoring and diagnosis of

vehicle health”, he said. “Vehicle is going to become a gadget like mobile phone. There is a new concept called software-defined vehicles, where features can be introduced into a vehicle through a software update. Now automobiles are not going to become a mechanical problem, but a software problem”, said Gagandeep Reehal, Co-founder, CEO, and CTO of Minus Zero, an autonomous mobility startup based in Bangalore.

Reehal said that Minus Zero researched the intersection of neuroscience and AI, to bridge the gap between human intelligence and machine intelligence. “We came up with the concept called Nature-inspired AI, a new way of solving autonomy of vehicles, inspired by human behavior, awareness of the surroundings and how we learn ourselves on the go”, he said.

“Autonomous vehicles sold in the right way, will be much safer than any human driver. That is why we need them”, he said. He further added that inducing reasoning capability was the biggest challenge for countries to adopt automotive AI technology.

Indian Institute of Management Ahmedabad’s (IIMA) 2023 report titled ‘AI in India: A Strategic Necessity’ pointed out that two-thirds of Indian companies were falling behind in terms of AI adoption and maturity.

“Collaborative robots are increasingly used in manufacturing. The integration of IoT (Internet of Things) sensors and data analytics in robotic systems is enhancing predictive maintenance and process optimization, further driving efficiency in the automotive sector”, said Atul Patil, Deputy General Manager, Marketing Department and Strategic Planning, Factory Automation and Industrial Division of Mitsubishi Electric India.

Patil said that there was also a growing emphasis on sustainable and energy-efficient manufacturing processes, with robots designed to reduce energy consumption and waste.

He said that Mitsubishi Electric’s ‘e-F@ctory’, leveraged digital technologies such as AI, big data, IoT, Edge Computing, and Advanced Robotics, offering them a technological ecosystem to achieve digital transformation in their manufacturing environment.